The 3D printing world is full of possibilities. You can print toys, art, decor, tools, and even replacement parts. But when it comes to functional prints, parts that must work, hold their shape, or withstand wear, you need the right filament. Choosing the best 3D print filament for functional parts means finding materials that are strong, reliable, and suited for real use. Not all filaments are equal. Some are too brittle. Others are flexible but not strong. Some resist heat. Others don’t. This article covers the top 3d printing filaments for functional applications. We’ll explore materials based on strength, flexibility, ease of use, and real-world performance.

If you’re printing brackets, gears, phone mounts, or even drone parts, read on. You’ll learn what to print with and why.

What Makes a Filament Functional?

Before diving into filament types, let’s define what “functional” means in this context. A functional 3D print isn’t just for show. It must:

- Hold weight or resist impact

- Operate under stress, pressure, or friction

- Be used regularly, not just occasionally

Resist heat or weather, depending on where it’s used

Functional parts demand durability, reliability, and precision.

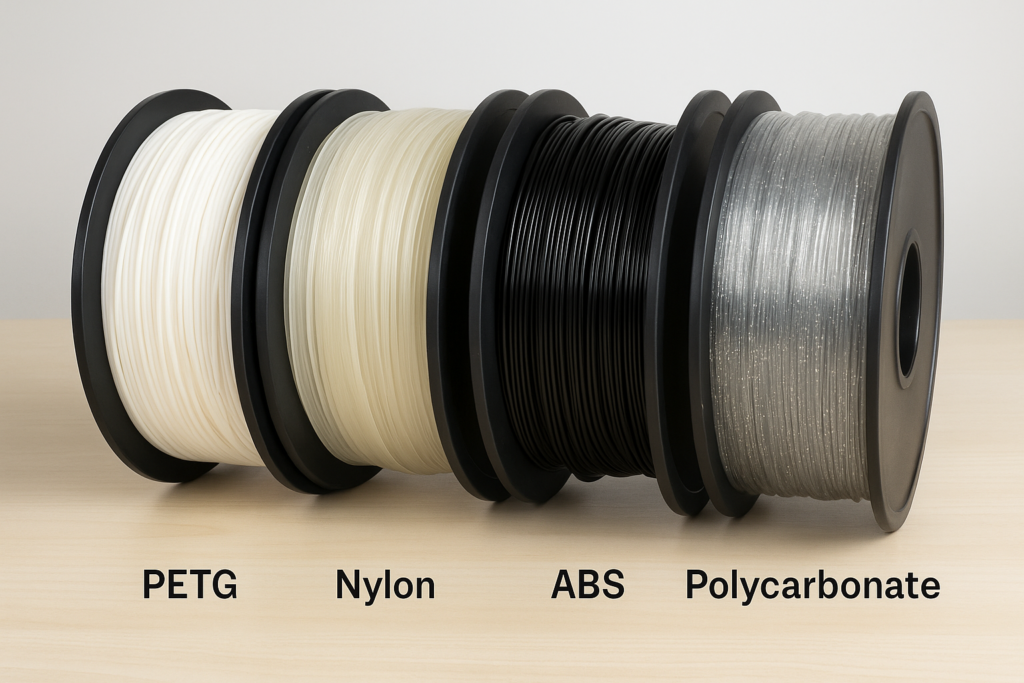

1. PETG – The Everyday Workhorse

PETG is a perfect blend of strength and flexibility. It’s stronger than PLA but easier to print than ABS.

Best for:

- Outdoor clips

- Camera mounts

- Tool holders

- Boxes or enclosures

Advantages:

- Great layer adhesion

- UV and moisture resistant

- Slightly flexible, so it resists snapping

Downsides:

- Not the best in high heat

- May string during print

PETG is a favorite for durable parts that won’t crack under pressure. It prints easily and works in many environments.

2. Nylon – Flexible and Impact-Resistant

Nylon is one of the strongest 3D printing filaments available. It’s flexible, tough, and hard to break.

Best for:

- Hinges

- Functional joints

- Wear-resistant parts

- Mechanical connectors

Advantages:

- High tensile strength

- Good wear resistance

- Flexes without cracking

Downsides:

- Needs dry storage

- Warps without a heated chamber

If you’re printing something that bends, moves, or needs to withstand real force, Nylon is ideal.

3. ABS – Industrial-Level Strength

ABS has been used in industrial applications for decades. It’s stronger than PLA and more heat-resistant than PETG.

Best for:

- Auto parts

- Mechanical tools

- Enclosures under stress

- Prototypes

Advantages:

- Good heat resistance

- Impact resistant

- Great for sanding or post-processing

Downsides:

- Warps easily

- Needs ventilation

ABS is tricky to print but delivers results. If your print environment is stable, it performs well.

4. Polycarbonate (PC) – Ultimate Toughness

Polycarbonate is used in helmets, car windows, and riot shields. That says enough.

Best for:

- High-strength gears

- Impact-proof cases

- Load-bearing brackets

Advantages:

- Excellent mechanical strength

- High heat resistance

- Very tough

Downsides:

- Needs very high print temps

- May need a heated chamber

PC isn’t for beginners, but it’s unbeatable for serious parts. It’s for when your print must not fail.

5. TPU – Flexible and Functional

TPU is not rigid like the others. But for parts that must bend and bounce back, it’s the best.

Best for:

- Gaskets

- Phone cases

- Shock-absorbing pads

- Cable clips

Advantages:

- Very flexible

- Good abrasion resistance

- Grippy and durable

Downsides:

- Harder to print with Bowden setups

- Slow printing speeds

TPU prints are perfect for anything soft, shockproof, or wearable. It’s great for low-speed moving parts too.

6. Carbon Fibre-Filled Filaments – Light and Stiff

Carbon fiber blends are filament materials like PETG, PLA, or Nylon filled with chopped carbon fiber.

Best for:

- Drone frames

- RC car parts

- Precision jigs

Advantages:

- Very rigid

- Lighter than metal

- Doesn’t warp as much

Downsides:

- Can wear down nozzles

- More brittle than the base material

If you want a clean, professional look and functional stiffness, carbon fibre blends deliver.

Choosing Based on Application

Here’s a simple breakdown:

Use CaseBest Filament

Outdoor or wet use PETG, ASA

Heat exposure ABS, Polycarbonate

Flexibility and movement, Nylon, TPU

Rigid, lightweight parts, Carbon Fibre Blends

Beginner-friendly strength PETG

You don’t need to use exotic materials for everything. Match the filament to the function. That’s the key.

Quick Tips for Stronger Functional Prints

- Increase infill: Use 40% to 100% for load-bearing parts

- Use more walls: 3 or more perimeter walls add strength

- Print slow: Lower speed means better adhesion

- Avoid weak layer lines: Orient the part to reduce layer tension

Good design matters as much as material choice. Print smart, not just strong.

Real-World Applications

Let’s say you’re fixing a broken bracket under your desk. PLA might snap. PETG won’t.

Need a custom handle for a tool? ABS will handle the grip and the heat.

Creating a camera gimbal? Nylon or TPU adds flexibility.

That’s the beauty of 3D printing—tailored parts for real tasks.

READ MORE – 3D Print Parol: How to Design and Print Your Own Filipino Lanterns

FAQs:

1. What is the strongest filament for 3D printing functional parts?

Polycarbonate is the strongest for high-load applications. It resists heat, pressure, and impact.

2. Is PLA good for functional parts?

Not really. PLA is brittle and not heat-resistant. It’s better for prototypes or aesthetic prints.

3. What’s the easiest strong filament to print with?

PETG is the easiest functional filament. It prints like PLA but is much stronger.

4. Can I use TPU for load-bearing prints?

TPU is not ideal for weight-bearing. It’s flexible, not rigid. Great for shock absorption, not heavy loads.

5. Which filament is best for outdoor parts?

PETG and ASA are best for exposure to the sun, rain, and weather. PLA and ABS can degrade over time when exposed to the outside.

Conclusion:

Functional 3D printing is not about flashy looks. It’s about performance. It’s about real-world strength, use, and durability. The best 3D print filament for functional parts depends on what your print needs to do. PETG offers balance. Nylon gives flexibility and toughness. ABS brings heat resistance. TPU adds elasticity. And polycarbonate handles the heavy loads. You don’t need the most expensive material. You need the right one. Choose well. Print smart. Build stronger.